Bell maintenance and service

PROTECT YOUR INVESTMENT

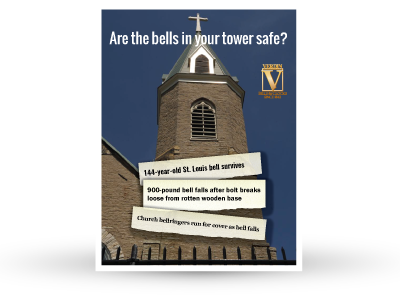

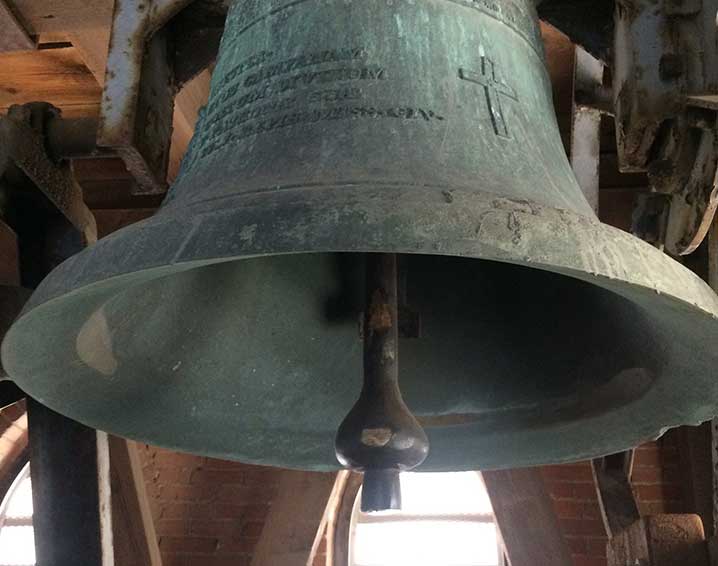

Over time, bell hardware becomes worn and fragile, making the ringing of the bells unsafe. An article in Sacred Places magazine highlights the importance of regular maintenance, inspection, and repair of bell ringing equipment. The Verdin Company™ can update your bell equipment to ensure it rings properly, is structurally safe in the tower, and that your church bells maintain the clear, warm sounds they originally had.

“WE TOOK OUR BELLS FOR GRANTED. BUT THE MOMENT OUR BELLS BECAME SILENT, THE COMMUNITY NOTICED.”

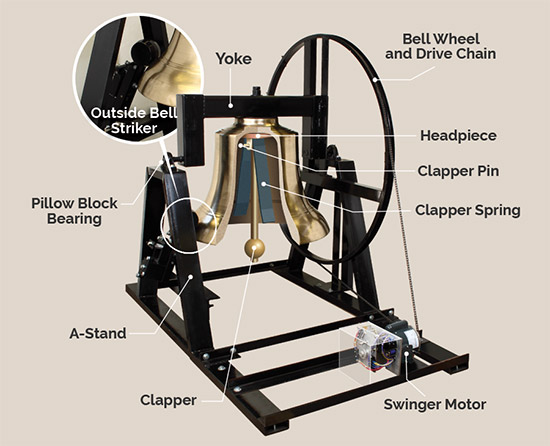

Verdin’s silent, precision-built swinging bell ringer is a custom engineered system that will ring any bell with the correct swing for maximum richness of tone. With Verdin’s swinging bell ringers, bells can be rung automatically or switch-controlled.

Verdin’s silent, precision-built swinging bell ringer is a custom engineered system that will ring any bell with the correct swing for maximum richness of tone. With Verdin’s swinging bell ringers, bells can be rung automatically or switch-controlled.